DST5H Series SIL 3 Incremental Rotary Encoder DST514-2048-003

Position Sensors & Encoders

58mm hollow shaft incremental functional safety encoder, SIL3/PLe, with TTL 5 Vdc output, 02048 ppr, radial M23 connector, and a key with a flexmount for industrial applications.

Applications: Industrial automation; automated guided vehicles; mills for lumber, steel, and other metals; printing and packaging equipment; food processing equipment; forming and die presses.

Industries

Distributors Stock

Part #DST514-2048-003

Need more information?

Contact us to request pricing, availability and customization options

Contact UsFeatures

- Usable up to SIL3 and Cat.4 / PLe according to IEC 61508 / EN ISO 13849

- Suitable for safe motor feedback according to IEC 61800-5-2

- Robust and excellent resistance to shock and vibration

- High protection level: IP65

- High temperature performance –20°C to +85°C

- 58mm standard size encoder

- Multiple shaft configurations: through hollow shaft: 9.52mm to 14mm. Other shaft configurations available (solid, blind, tapered)

- Wide choice of connection configurations

- Power supply 5Vdc or 11 - 30Vdc

- Digital TTL/RS422, HTL or sine/cosine 1Vpp output

- Resolutions up to 2500ppr

Downloads

- DST5H Series Incremental Safety Encoder Datasheet

- DST5h Series Installation Guide

- DST5h Series Incremental Safety Encoder (Connector) PDF Drawing

- DST5h Series Incremental Safety Encoder (Connector) STEP Drawing

- DST5h Series Incremental Safety Encoder (Connector) DWG Drawing

- TUV Functional Safety Certificate

Specifications

| Material | Cover: coated zinc alloy Body: aluminum Shaft: AISI 303 stainless steel |

| Bearings | 6803 series - sealed |

| Maximum Loads | Axial: 20 N Radial: 40 N |

| Shaft Inertia | < 7,200 g.mm2 |

| Static/Dynamic torque | 25 / 120 mN.m |

| Permissible max. speed | 9,000 RPM |

| Continuous max. speed | 6,000 RPM |

| Theoretical mechanical lifetime L10h (A) | >24 X 109 turns / 100,000 hours |

| Encoder weight (approx.) | 0.28 kg |

(A)Continuous max. speed – ½ max. load – according to ISO 281: 1990, L10

| Electronic Version | Output signals | Operating Voltage +V | Supply current | Current per channel pair | Short circuit protected | Reverse polarity protected | PFD | PFH | MTTFd | DC |

| 2G2 | Digital TTL RS422 |

5V +/-5%(C) 250 mA |

100mA with no load | 40 mA | Yes | Yes | 7.51E-05 | 8.58E-10 | 1331 | HIGH |

| 5G2 | Digital TTL RS422 |

11-30V(C) 250 mA |

100mA with no load | 40 mA | Not to +V | 9.52E-05 | 1.09E-09 | 1050 | ||

| 5G5 | Digital HTL | 11-30V(C) 250 mA |

100mA with no load | 40 mA | Yes | 9.52E-05 | 1.09E-09 | 1050 | ||

| 2WT | Sine Cosine 1Vpp | 5V +/-5%(C) 250 mA |

70 mA with no load | 10 mA | Yes | 4.29E-05 | 4.90E-10 | 2328 | ||

| 5WT | Sine Cosine 1Vpp | 11-30V(C) 250 mA |

70 mA with no load | 10 mA | Not to +V | 6.60E-05 | 7.53E-10 | 1515 |

(C) Device must be supplied by a Class 2 LPS or SELV/PELV limited energy source ≤60V

| Protection (EN 60529) | IP65 |

| Salt Spray (EN 60068-2-11 part 2) | 96h |

| Humidity (EN 60068-2-38) | 93% @ 65°C |

| Shock (EN 60068-2-27) | ≤ 500m.s-2 (6 ms, half sine) |

| Vibration (EN 60068-2-6) | ≤200m.s-2 (10…2000Hz) |

| Operating temperature | -20 to 85°C (encoder T°) |

| Storage temperature | -20 to 85°C |

| EMC Immunity Test | EN 61000-6-2, increased levels |

| EMC Emission Test | EN 61000-6-4, increased levels |

| Isolation | 1000 Veff |

| Functional safety | IEC 61508 IEC 62061 ISO 13849-1 IEC 61800-5-2 |

| Family | Shaft | Mechanical option | Supply + Output stage + Output signals | Channels | Resolution | Output Termination | Output Orientation | Cable Length | Accessories* |

| DST5H | E3 = 9.52 mm E4 = 12.7 mm 10 = 10 mm 12 = 12 mm 14 = 14 mm |

Blank: No option (standard back clamping ring) OM: Face clamping ring P4: Shaft with positive locks |

2G2: 5Vdc, TTL RS422 5G2: 11- 30Vdc, TTL RS422 5G5: 11- 30Vdc, HTL 2WT: 5Vdc, Sine 1 Vpp (analog) 5WT: 11- 30Vdc, Sine 1 Vpp (analog) |

9: Digital electronics AA/ BB/ ZZ/ B before A, CW viewed from flange side Z gated A&B N: Analog electronics SS/ CC/ ZZ/ C before S, CW viewed from flange side Z ungated Contact factory for other configurations |

250, 256, 360, 500, 512, 1000, 1024, 1500, 2000, 2048, 2500 | G6: M23 12 pins CW G8: M23 12 pins CCW GM: M12 8 pins GP: PUR cable 12 wires G3: PVC cable 8 wires U3: PVC Cable 8 wires GC: PUR cable 8 wires |

R: Radial | xxx: Cable Length (ex.: 020 = 2 Meters) Blank: No Cable |

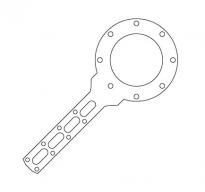

CS****: Key for positive lock CSS3**: Key + 9445/063 stator coupling (for DST5Hxx/OM/) CSDX**: Key + 9445/044 stator coupling CSBA**: Key + 9445/047 Tether arm |