| Aviation | Construction | Custom Applications | Lumber | Mining | Utilities | Waste | Transportation |

A Major Airline

When a major airline had a safety concern with their ground crew lavatory service trucks, they had to look for an out of the box solution to correct the issue before it got out of hand. PreView Radar met their key requirements to implement: detection of both stationary and moving objects, ability to work through extreme vibration, and provide a consistent detection pattern in the most extreme weather conditions.

Learn More

JBT Corporation

Billions of dollars are spent every year repairing aircraft hit by ground support equipment. Cargo loaders come right up to the side of the aircraft so they have a higher risk of potentially causing damage. The role of the PreView Radar sensors is to detect when the loader is approaching the fuselage, and when the loader gets within a specified distance, to send a signal that will slow it down.

Learn More

IMCCO

Machines, vehicles, and ground employees must work in close proximity when working on an aggregate site like Idaho Materials and Construction (IMCCO), a division of Oldcastle. The mixture of these elements can result in a loud environment where backup alarms become less effective and intrusive to the surrounding neighbors. Because of Oldcastle’s corporate commitment to eliminating hazards and improving operations, IMCCO contacted PreView Radar.

Learn More

Autonomous Solutions, Inc.

“LIDAR gives really high-resolution information, but it is susceptible to unwanted returns from dust and rain and snow. Our radars complement this information by being able to penetrate harsh conditions to verify the existence of actual obstacles.”

Learn More

Equipe GeoSolutions

To improve the productivity of its customers, Equipe Group began looking for ways to replace these widely disliked drill gates with more modern safety technology. “We looked at infrared,” Spires says. “We looked at laser scanners. We looked at ultrasonic. We finally decided that the best solution was short-range radar. That’s when we started talking with PreView Radar.”

Learn More

Sperling Railway Services, Inc.

With machinery that’s moving this slowly, people tend to walk down the center of the track without paying much attention to the equipment behind them. They’re swinging sledgehammers or using pry bars and forget about the slow-moving machine coming up behind them. We needed to find a way to engineer out the potential for injury or collision between the plate monster and other people or equipment on the same track.

Learn More

World Leading Lumber Mill

When a world leading lumber mill saw the repair cost of a collision between a front loader and a truck, they started looking for a way to prevent such accidents. Their immediate solution was to adapt a radar detection sensor from a passenger vehicle. When they saw that the technology might work on heavy-duty equipment, they set out to find an industrial-grade solution, and found PreView Radar.

Learn More

Imerys S.A.

Installation of Sensata's PreView Radar systems has enabled Bruce Coggin, Senior Environmental Health and Safety Manager, to achieve two goals at the same time. On one hand, he can continue to decrease the odds that an employee will ever be struck by moving equipment. At the same time, he can reduce the significant costs incurred by property damage-type accidents. Small wonder, then, that he plans to continue expanding use of these heavy-duty safety systems.

Learn More

Sterling Ventures, LLC

Sterling Ventures, LLC runs a 1,000-acre underground limestone mine in Verona, Kentucky. In this dusty, sometimes cramped, 3-level environment, 16-ton L220 loaders must carefully navigate around obstacles to get the limestone into haul trucks. If an operator backs into one of the 50-foot-wide ribs that support the mining area, damage to the vehicle’s counterweights can cost as much as $30,000 to repair or replace. Sterling mounted Sensata's PreView® Radar on the back of one such loader, and that machine hasn’t been involved in a single accident since. With its pilot test successful, Sterling is ready to install the PreView systems on the rest of its L220 loaders.

Learn More

World Leader in Fatigue and Distraction Monitoring

If you want to get a sense of just how big open-pit haul trucks can get, consider this: These behemoths need as many as eight radar sensors and cameras to know what’s in front, along with the sides, and behind the truck. To help operators avoid collisions, a leader in accurate fatigue and distraction monitoring systems, brought together advanced technologies to create a powerful collision avoidance solution. When the company wanted to integrate radar sensing to complete its solution, it chose PreView Radar Electronics®—not only because of its advanced collision avoidance technology but because of our reputation for high-quality and service.

Learn More

Eugene Water & Electric Board

Our calculations from the tests we ran showed that a backup camera’s view range needed to be at least 170 degrees to meet the new standards. Other cameras we looked at had ranges between 130-150 degrees—not enough to provide the required close-up view behind the vehicle. We did our research and found that our PreView Mini Cam could go all the way up to 180 degrees—and met the response time criteria as well.

Learn More

Montana-Dakota Utilities

With a service area spanning eight Northern and Pacific Northwest states, Montana-Dakota Utilities Co. keeps a lot of drivers and trucks on the road. They install and repair electric and gas utility lines in cities, suburbs, and in the countryside, often in extreme weather conditions. To help their drivers operate more safely, Montana-Dakota has been systematically upgrading its trucks with PreView® Radar side and rear detection systems. The results include fewer rear-end and side blind zone collisions, improved safety, and lower installation costs.

Learn More

City of Bunnell

Less than six months after he took over the City of Bunnell’s solid waste department, Perry Mitrano was subbing for one of his drivers and came within inches of killing someone. It was an anguished, unforgettable moment. And it reaffirmed to Mitrano, his department, and the residents of Bunnell that their modest investment in a PreView® Radar System was worth much more than the cost of the equipment itself.

Learn More

Honolulu Disposal

The combination of frequent storms, tourists, hungry rodents, and corrosive ocean air poses a challenge for all truck fleets operating in Hawaii. But for Honolulu Disposal Service’s garbage disposal trucks, the challenges can be even greater. Its trucks typically operate in bad weather and early morning hours when visibility is poor. They navigate busy, narrow urban streets and alleys. And despite all of their warning signs and sounds, these hulking vehicles seem to go unnoticed as people make their way home, to work, and to the beach. To help its drivers operate as safely as possible, Honolulu Disposal equips its trucks with cameras, and with PreView Radar Systems.

Learn More

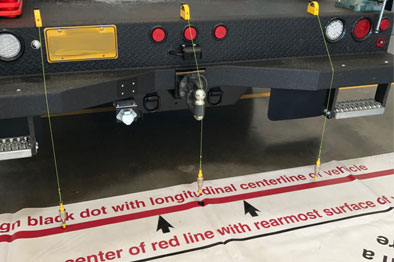

RADC Trailer Reversing System

Reversing any vehicle can be challenging. Reversing a large truck can be even more difficult. Now add a long trailer full of cargo and imagine the increased challenge for even the most seasoned drivers. Enter Aspöck UK and the RADC trailer reversing system to avoid the costs associated with damage caused by colliding with the dock. However, Aspöck UK knew they could improve performance and safety for reversing vehicles with a more rugged and reliable radar. Enter the PreView Sentry® from Sensata Technologies. Designed for the most rugged of environments Sentry® was the perfect solution to add the required dependability to the RADC.

Learn More